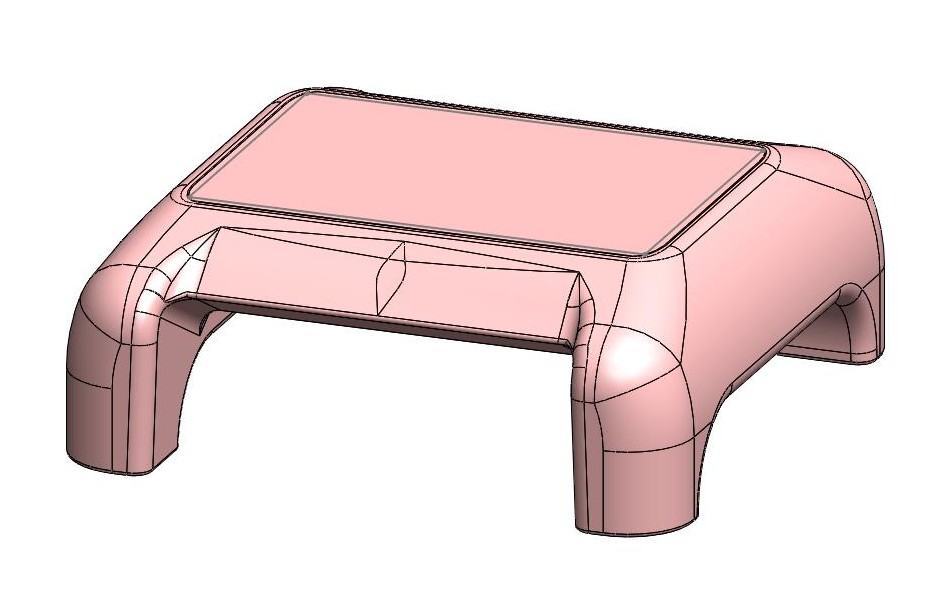

We just finished a new project called the “Brittlet” with local entrepreneur Brittany Lammon. It’s an innovative hair tool that saves you time by securing bobby pins on your wrist with a magnetic band and easily opening the bobby pins with a plastic clip on top. Brilliant! From the start of the project, I knew that Brittany was a smart, forward-thinking individual, namely because she already had the innovative bobby pin opener designed and manufactured. When a client shows up with a prototype, minor modifications are usually needed to make the piece moldable and affordable. However, the Brittlet required no modifications to the original design.

We just finished a new project called the “Brittlet” with local entrepreneur Brittany Lammon. It’s an innovative hair tool that saves you time by securing bobby pins on your wrist with a magnetic band and easily opening the bobby pins with a plastic clip on top. Brilliant! From the start of the project, I knew that Brittany was a smart, forward-thinking individual, namely because she already had the innovative bobby pin opener designed and manufactured. When a client shows up with a prototype, minor modifications are usually needed to make the piece moldable and affordable. However, the Brittlet required no modifications to the original design.

At Blue Ring Technologies, we have a straightforward way of creating a mold for a client. We first use our in-house CNC machine to make a graphite mold, which accurately duplicates the item to within .001 of an inch. The graphite is conductive so by using an Electric Discharge Machining (EDM) manufacturing process we get the desired shape through electrical discharges. Once the graphite is ready, we then use our EDM machine to slowly etch out the cavity into our mold. Once the mold is completed, we place it into our in-house Injection Mold Machine. The plastic parts can then be created by the hundreds or even thousands. Simple, right? Not quite…there is actually extensive engineering and years of experience behind the process to perfectly duplicate what our clients have worked so hard on. Not only were we able to create the final pieces of the Brittlet, but we also did it in record time to meet her Launch Party deadline! We were delighted to be invited to the launch party to celebrate this new, innovative product with Brittany. Seeing the final product firsthand, I was very impressed by its overall quality and usefulness. In other words, if you’ve ever had bobby pin frustrations, then this simple hair tool is the solution you’ve been waiting for. For more information, check out the website at http://www.brittlet.com/

At Blue Ring Technologies, we have a straightforward way of creating a mold for a client. We first use our in-house CNC machine to make a graphite mold, which accurately duplicates the item to within .001 of an inch. The graphite is conductive so by using an Electric Discharge Machining (EDM) manufacturing process we get the desired shape through electrical discharges. Once the graphite is ready, we then use our EDM machine to slowly etch out the cavity into our mold. Once the mold is completed, we place it into our in-house Injection Mold Machine. The plastic parts can then be created by the hundreds or even thousands. Simple, right? Not quite…there is actually extensive engineering and years of experience behind the process to perfectly duplicate what our clients have worked so hard on. Not only were we able to create the final pieces of the Brittlet, but we also did it in record time to meet her Launch Party deadline! We were delighted to be invited to the launch party to celebrate this new, innovative product with Brittany. Seeing the final product firsthand, I was very impressed by its overall quality and usefulness. In other words, if you’ve ever had bobby pin frustrations, then this simple hair tool is the solution you’ve been waiting for. For more information, check out the website at http://www.brittlet.com/