Engineering and Prototype Drawing Services

All too often at Blue Ring Technologies we run into the same problem. A client wants to manufacture a particular plastic product which they may have designed themselves, or had designed by an industrial designer. We inspect the file and quickly find that the design is completely un-manufacturable. This issue arises in our community over and over again. In this blog, I want to address some of the common look outs you can use to review the design before taking to injection molding manufacturing. If possible, please consult with us at Blue Ring Technologies before you invest time and money in the project.

Uniform Wall Thickness

One of the most common issues we see is that in the world of plastics we cannot make parts extremely thick. However, there are ways to work around the limitations this causes. Typical Resin Thicknesses are shown in the chart below:

| Typical Plastic Resins | Inches |

| ABS | 0.045 – 0.140 |

| Acrylic | 0.025 – 0.500 |

| Nylon | 0.030 – 0.115 |

| Polycarbonate | 0.040 – 0.150 |

| Polyethylene | 0.030 – 0.200 |

| Polypropylene | 0.025 – 0.150 |

| Polyurethane | 0.080 – 0.750 |

Material Selection

Plastic has different suggested wall thicknesses, strengths, and weaknesses. It is very important that the part is designed with a specific material from the beginning. Please read one of our previous blogs about material selection to understand the differences between them.

https://blueringtechnologies.com/plastics/

Parting Line

Selecting the parting line of parts is of the utmost importance in plastic manufacturing. Undercuts, cams, and sliders all affect the engineering design of the parts. The parting line is usually selected from the part orientation in which the mold is open and closed during the injection mold process. During the engineering design process, you can create the design in such a way as to create a simplified parting line that will ultimately save you in mold cost.

Form-Fitting Assembly and Stress Simulation

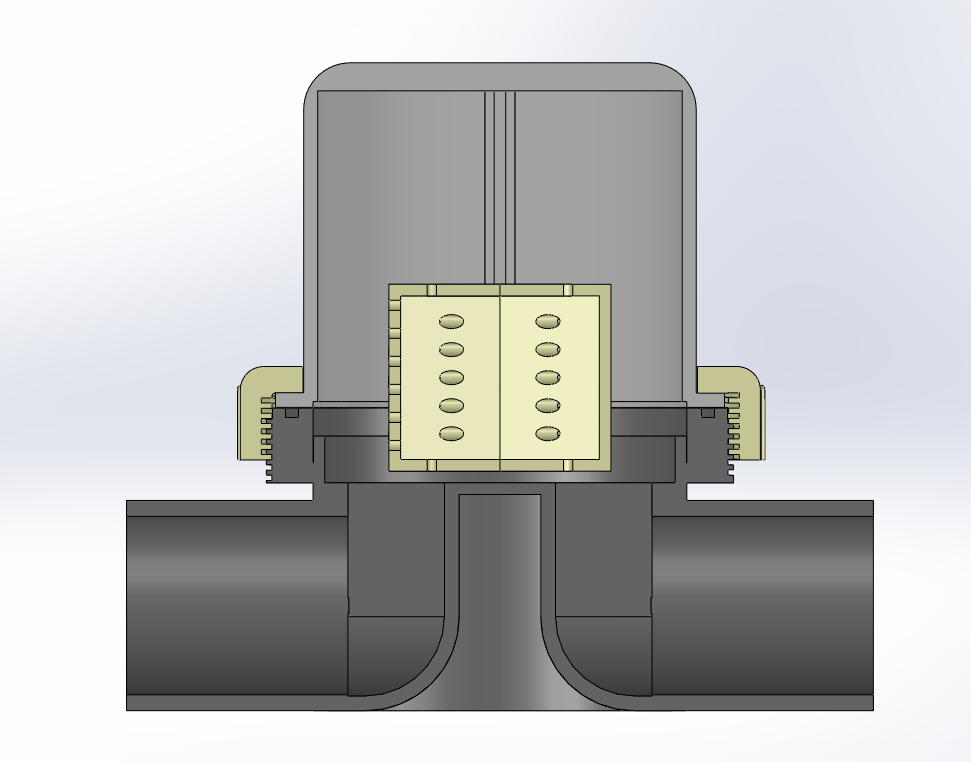

All too often we see files that look acceptable; however, their parts are never simulated to see if each form-fits into the others. In engineering school one of the first things you learn is to give tolerance to parts, something which is commonly overlooked by designers, with disastrous results. A 3D engineering file should be mated and assembled to simulate how parts are form-fitted, as shown below.

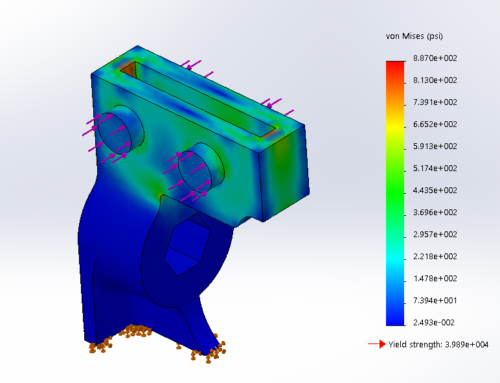

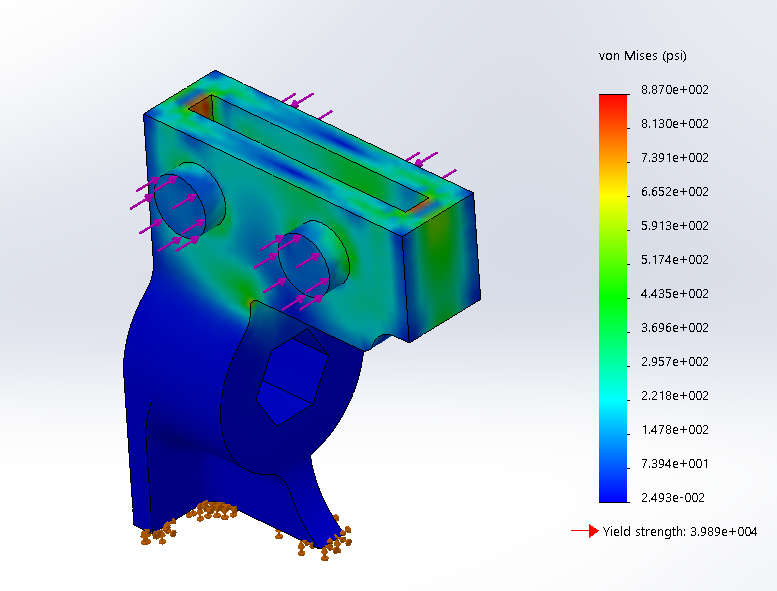

We also commonly encounter problems in the selection of material and the possible stress forces applied to the part. This can cause clients much heartache when their product is tested or used in the field only for part to be cracked or broken due to a stress encounter. It is a good idea to use some of the stress simulations below to properly understand failure points and how these can be resolved through design.

Engineering Drawing Prototype Services

Blue Ring Technologies

At Blue Ring Technologies, we pride ourselves on our ability to design, engineer, simulate, prototype, and manufacture everything in our own facility. We are a unique shop and we cover a vast range of factors that will ultimately save you time and money. Please take into consideration all these factors next time you take on a project, and give us a call at 305-707-4251. We will be more than happy to guide you through the process of product development.