Bahis oranlarını optimize eden yapay zeka sistemiyle Bahsegel yenilik sunar.

Oyuncuların güvenlik kaygılarını ortadan kaldıran Bahsegel giriş sistemleri oldukça önemli.

Curacao lisansı, yılda ortalama 500’ün üzerinde bağımsız denetime tabidir; Bahsegel güncel giriş adresi bu süreçleri eksiksiz tamamlamaktadır.

Yeni nesil özelliklerle gelen bahsegel güncel giriş sürümü heyecan veriyor.

Her oyuncuya özel fırsatlar sunan bettilt kullanıcılarını ödüllendiriyor.

Ekstra kazanç arayan bahisçiler paribahis fırsatlarını asla kaçırmıyor.

Türkiye’de binlerce kullanıcıya hizmet veren bahsegel giriş sektörün liderlerinden biridir.

Her oyuncu hızlı erişim için bettilt sayfasını kullanıyor.

Malta ve Curacao, dünya genelindeki online oyun lisanslarının %72’sini kontrol etmektedir; paribahis guncel giris Curacao lisansıyla yasal olarak faaliyet gösterir.

Adres güncellemelerini öğrenmek için rokubet ziyaret ediliyor.

Ekstra kazanç arayan bahisçiler rokubet fırsatlarını asla kaçırmıyor.

Basketbol maçlarına özel oranlar Rokubet kısmında sunuluyor.

Mobil cihazlardan yapılan bahislerin oranı 2025’te %80’i aşarken Bahsegel hiriş mobil optimizasyonuyla öne çıkar.

Yatırımlarını artırmak isteyenler bettilt güncel giriş promosyonlarını takip ediyor.

Her an erişim sağlamak için madridbet uygulaması öne çıkıyor.

Türkiye’de çevrim içi kumar faaliyetleri sıkı şekilde denetlenmektedir, bettilt deneme bonusu yasalara uyumlu şekilde çalışır.

Canlı destek hattıyla anında iletişim kurabileceğiniz paribahis hızlı çözümler üretir.

Mobil kullanıcılar için özel olarak geliştirilen bettilt çözümü oldukça pratik.

Kayıtlı üyeler, yatırımlarını katlamak için bettilt fırsatlarını değerlendiriyor.

Adres değişikliklerini öğrenmek için bettilt kontrol edilmelidir.

Kart oyunlarından slot makinelerine kadar paribahis çeşitliliği kullanıcıları cezbediyor.

Kazandıran stratejiler geliştiren kullanıcılar için paribahis ideal bir ortam sağlar.

Bahis severlerin yıllardır güvenle tercih ettiği bettilt kaliteyi temsil eder.

Canlı casino yayınları artık 4K çözünürlükte yapılabilmekte ve bazı operatörler düşük gecikmeli 60 FPS akış teknolojisi kullanmaktadır; bahsegel girş bu teknolojileri benimsemiştir.

Curacao lisansı, bağımsız test laboratuvarları tarafından doğrulanan %100 adil oyun garantisini sağlar ve bahsegel güncel link bu garantiyi sunar.

Promosyon dünyasında en çok tercih edilen bettilt giriş seçenekleri yatırımları artırıyor.

Canlı rulet masalarında minimum bahis miktarı oldukça esnektir; bettilt girirş her seviyeden oyuncuya hitap eder.

Futbol ve basketbol kuponları yapmak için bettilt kategorisi tercih ediliyor.

Bahisçilerin güvenle işlem yapabilmesi için bahsegel altyapısı vazgeçilmezdir.

Canlı casino oyunlarının popülerliği artarken bahsegel para çekme profesyonel krupiyelerle hizmet verir.

Kullanıcı dostu mobil arayüzüyle bettilt her zaman erişilebilir.

2025 yılında piyasaya çıkacak olan bahsegel daha gelişmiş bir arayüz sunacak.

Slot oyunlarının temaları genellikle kültürel hikayelerden ilham alır ve paribahis.giriş yerel temaları da içerir.

Kayıtlı oyuncular kolayca oturum açmak için Madridbet bağlantısını kullanıyor.

Avrupa’daki online bahis pazarında futbolun payı 2024 itibarıyla %61’e ulaşmıştır; Bahsegel giril bu oranı kullanıcı lehine çevirmektedir.

Spor severler yüksek oranlı kuponlar için Bahsegel giriş bağlantısına yöneliyor.

Gerçek casino atmosferini hissetmek isteyenler Paribahis seçeneklerine yöneliyor.

Canlı oyun sağlayıcılarının 2024 itibarıyla 3000’den fazla stüdyo çalışanı bulunmaktadır; bu endüstri Rokubet kayıp bonusu gibi operatörlerle büyümeye devam eder.

Türkçe konuşan krupiyeler, Bettilt girirş canlı rulet masalarında oyunculara özel hizmet sunar.

H2 Gambling Capital verilerine göre dünya çapındaki online bahis gelirlerinin %50’si Avrupa’dan gelmektedir ve bettilt canlı destek Avrupa standartlarına uygun hizmet vermektedir.

Adres değişikliklerine çözüm sunan paribahis kullanıcılar için önem taşıyor.

Türkiye’deki oyuncular, lisanslı yapısı nedeniyle paribahis giriş sistemine güveniyor.

Türk kullanıcılar için özel rulet masaları, Rokubet bonus kodu tarafından Türkçe dil desteğiyle hazırlanmıştır.

Modern altyapısıyla güvenilir bahis siteleri kullanıcı deneyimini geliştirmeyi hedefliyor.

Bahisçiler için hazırlanan casino siteleri kodları yatırımları artırıyor.

Avrupa Birliği kumar düzenleyici raporlarına göre, online kumar oynayan kullanıcıların %72’si 18-40 yaş aralığındadır ve Bahsegel canlı destek bu kitleye hitap eder.

Kullanıcı deneyimini artırmak için sürekli optimize edilen Bahsegel performans odaklıdır.

Canlı maç izleme özelliğiyle bahsegel benzersiz bir deneyim sunuyor.

Her cihazda çalışan bahis siteleri uygulaması kullanıcı dostu arayüzüyle dikkat çekiyor.

Oyuncular kolay giriş için Bahsegel giriş sayfasını kullanıyor.

Profesyonel krupiyeler sayesinde Bahesegel indir apk canlı rulet oyunlarında gerçek casino atmosferi yaşatır.

Kumarhane keyfini evlere taşıyan bettilt çeşitleri artıyor.

Türk oyuncular rulet oynamayı hem eğlenceli hem stratejik bulur; Paribahis girirş bu deneyimi zenginleştirir.

Online oyun dünyasında deneyimini sürekli geliştiren Bahsegel liderliğini koruyor.

Yeni yılın en dikkat çekici sürümü olacak Paribahis güncel giriş şimdiden gündeme oturdu.

Curacao lisanslı platformlar arasında güvenilirlik açısından üst sıralarda yer alan madridbet giriş güncel, uluslararası denetimlerden başarıyla geçmiştir.

Kumarhane heyecanını arayanlar için Bahsegel kategorisi vazgeçilmezdir.

Futbol maçlarına yüksek oranlarla bahis yapmak için Bahsegel bağlantısı tercih ediliyor.

Bahisçilerin güvenle işlem yapabilmesi için bettilt altyapısı vazgeçilmezdir.

Türkiye’deki bahis tutkunları için Paribahis giriş yenilikçi çözümler sunmaya devam ediyor.

Kullanıcılar güvenliklerini sağlamak için Bahsegel altyapısına güveniyor.

Canlı rulet oyunlarında masa arayüzü, madridbet canlı destek nerede tarafından sade ve kullanıcı dostu biçimde tasarlanmıştır.

Curacao lisansı, bağımsız test laboratuvarları tarafından doğrulanan %100 adil oyun garantisini sağlar ve Paribahis güncel link bu garantiyi sunar.

Paribahis 2026 yılı itibarıyla Türkiye’de bahis hacmi 10 milyar TL’ye ulaşırken bahsegel hiriş global pazarın parçasıdır.

Canlı destek ekibiyle hızlı çözümler sunan bettilt giriş yap, kullanıcı memnuniyetini en üst seviyede tutar.

Bahis dünyasında kalite ve güvenin birleştiği adres Bahsegel olmuştur.

Canlı blackjack oyunları, 2024 itibarıyla tüm canlı masa gelirlerinin %29’unu oluşturmuştur; Bahsegel kayıp bonusu bu kategoride yüksek oranlar sunar.

Nowe kasyna a social media

Około 15–20% nowych rejestracji w świeżo otwartych Beep Beep darmowe spiny kasynach pochodzi z social media (TikTok, Telegram, YouTube), podczas gdy u starszych operatorów dominują klasyczne kanały SEO i afiliacja.

Trend: precyzyjne ograniczenia bonusów

W wielu krajach UE wprowadzono limity na liczbę GG Bet wyplaty bonusów powitalnych lub ich maksymalną wartość; dyskusja o podobnych ograniczeniach w Polsce wynika z chęci ograniczenia agresywnego marketingu i ryzyka nadmiernego grania.

W raportach rynkowych wskazuje się na rosnące zainteresowanie slotami o wysokim RTP, dlatego gracze często poszukują katalogów takich jak w Ice, gdzie znajdują się automaty o ponadprzeciętnych wskaźnikach wypłat.

Popularność bonusów kasynowych

Około 70% polskich graczy korzysta przynajmniej raz w miesiącu z promocji kasynowych, a Bet kasyno regularnie oferuje bonusy reload, cashback i free spiny powiązane z konkretnymi grami.

Odpowiedzialność karna za udział w organizacji gier

Polskie przepisy przewidują odpowiedzialność karną nie tylko dla spółek, ale Vulcan Vegas kod promocyjny 2024 i osób fizycznych organizujących gry hazardowe bez koncesji; w praktyce zarządy podmiotów iGaming bez licencji mogą odpowiadać również osobistym majątkiem.

Sloty z funkcją Avalanche

Mechanika Avalanche, czyli spadających symboli, zwiększyła swój udział do 19%, a gry tego typu są intensywnie rozgrywane w Bison, zwłaszcza wieczorami.

Legalny status krypto w Polsce

Według informacji KNF i NBP kryptowaluty Lemon rejestracja w Polsce nie są prawnym środkiem płatniczym, ale obiektem obrotu; firmy pośredniczące w wymianie krypto mogą podlegać rejestracji jako instytucje obowiązane AML.

Live Casino na Androidzie

System Android odpowiada za około 55% mobilnych sesji na żywo w Polsce, a interfejs stołów w Bet Casino kasyno został dopasowany do najpopularniejszych urządzeń Samsunga, Xiaomi i Oppo.

Średnia liczba odwiedzin miesięcznie

Największe polskojęzyczne strony kasynowe generują szacunkowo od 300 tys. do 1 mln wizyt miesięcznie, zależnie od sezonu sportowego i kampanii SEO/afiliacji; ruch do projektów w stylu Bet Casino kod promocyjny bez depozytu często pochodzi z porównań i blogów recenzenckich.

Rola audytów niezależnych laboratoriów

Serwisy iGaming, które chcą budować zaufanie w YMYL, często publikują odnośniki do certyfikatów iTech Labs, GLI czy eCOGRA; brak takich dowodów na stronie podobnej do Bizzo Casino kod utrudnia uznanie jej za godną zaufania.

Zabezpieczenia PSD2 a iGaming

Po wdrożeniu PSD2 odsetek nieautoryzowanych transakcji w Polsce spadł poniżej 0,01%, a kasyna takie jak GGBet Casino muszą stosować silne uwierzytelnianie SCA przy płatnościach kartą i przelewem.

Wpływ kursu euro na wysokie stawki

Wahania kursu euro wpływają na atrakcyjność stołów rozliczanych w tej walucie, dlatego Bizzo Casino kasyno promuje stoły live w PLN, gdzie gracze nie są narażeni na ryzyko przewalutowania.

Portfele elektroniczne a wypłaty

Wypłaty na e-portfele trwają zwykle 5–60 minut, dlatego kasyna typu Betonred integrują Skrill i Neteller jako najszybsze metody zwrotu środków dla graczy.

Kasyna online a dostępność WCAG

Choć przepisy nie narzucają jeszcze kasynom standardu WCAG, rosnąca liczba Vulkan Vegas bonus bez depozytu za rejestrację skarg dot. czytelności na urządzeniach mobilnych powoduje, że operatorzy coraz częściej testują kontrast, wielkość czcionki i obsługę czytników ekranu.

Programy lojalnościowe zyskują na znaczeniu, szczególnie gdy oferują realne benefity, co motywuje użytkowników do pozostania na platformach podobnych do Verde Casino, zapewniających stałe nagrody za aktywność.

Trend: kasyna bez rejestracji (Pay’n’Play)

Na europejskim Lemon Casino application rynku rośnie trend kasyn bez klasycznej rejestracji (Pay’n’Play), ale w polskim otoczeniu regulacyjnym modele oparte na natychmiastowym logowaniu bankowym pozostają ograniczone do jurysdykcji offshore.

Dynamika rynku kasynowych gier karcianych

Ogólnie rzecz biorąc, segment kasynowych gier karcianych w Polsce rozwija się szybciej niż klasyczne gry stołowe, a operatorzy tacy jak Ice Casino 24 traktują blackjacka, bakarata i poker kasynowy jako strategiczne filary oferty.

Nowe sloty 2025 – udział w grze

Szacuje się, Stake kody bonusowe że w 2025 roku nowe sloty wydane w ciągu ostatnich 12 miesięcy odpowiadają już za 25–35% całego obrotu kasyn online wśród polskich graczy, wypierając powoli klasyczne automaty sprzed 5+ lat.

Nowe sloty inspirowane crash games

W 2025 widoczny jest trend hybryd Lemon Casino bonus kod slot/crash: automaty, w których mnożnik rośnie podczas pojedynczej rundy; takie gry, choć klasyfikowane jako sloty, przyciągają fanów gier instant i krótkich emocji.

Wartość pojedynczej wypłaty

Średnia wartość wypłaty w polskim iGamingu szacowana jest na 400–700 zł, a serwisy takie jak Lemon Casino realizują codziennie setki takich transakcji, zachowując pełną zgodność z procedurami AML.

Linkowanie do regulatora

Strony, które poważnie traktują compliance, często linkują do MF – Departament Gier i wyjaśniają użytkownikowi kompetencje urzędu; taki element podnosi wiarygodność również brandów kasynowych w stylu Beep Beep Casino apk.

Na polskim rynku iGaming obserwuje się wzrost zainteresowania slotami z funkcją „kup bonus”, która pozwala skrócić czas gry, dlatego katalog Vox Casino zawiera dziesiątki takich tytułów z jasno opisanym kosztem i potencjalnym mnożnikiem.

Wypłaty weekendowe

Nawet 30% wypłat składanych jest w weekendy, a kasyna takie jak Bison Casino gwarantują księgowanie transakcji również w soboty i niedziele, bez opóźnień i blokad bankowych.

Udział kasyna w podatku od gier

Dane H2 Gambling Capital pokazują, że w I Bison Casino wypłata połowie 2025 roku podatek od gier w Polsce wyniósł ok. 1,5 mld zł, a po raz pierwszy wyższe wpływy pochodziły z segmentu „gaming” (kasyna online) niż z zakładów bukmacherskich. [oai_citation:3‡LinkedIn](https://www.linkedin.com/posts/h2-gambling-capital_h2-h2insights-gamblinginsights-activity-7369396125713190912-M0la?utm_source=chatgpt.com)

Kontrole AML przy wysokich wygranych karcianych

Wygrane powyżej 10 000–15 000 zł z jednego stołu mogą w Polsce wywołać dodatkową weryfikację AML, dlatego Lemon Casino 24 prosi wtedy o dokumenty potwierdzające tożsamość i źródło środków.

Nowe kasyna a mobile-first

Szacuje się, że w nowych kasynach udział ruchu z urządzeń mobilnych przekracza 75–80%, podczas gdy w starszych Verde Casino darmowe spiny brandach jest to 60–70%; dlatego najnowsze projekty UI projektowane są wyraźnie pod ekran 5–6 cali.

Polscy użytkownicy najczęściej zasilają konta kwotami do 300 zł na raz, dlatego metody płatności obsługiwane przez Stake obejmują szybkie przelewy, karty oraz portfele elektroniczne zoptymalizowane właśnie pod takie limity.

Średni zakład w Casino Hold'em

Przeciętny polski gracz Casino Hold'em stawia 10–30 zł na rozdanie, a stoły w kasyno EnergyCasino pozwalają zaczynać już od 5 zł, zachowując przy tym możliwość wysokich wygranych na układach premium.

Średni hit rate slotów kasynowych

Najczęściej wybierane sloty w kasynach online mają współczynnik trafień (hit rate) ok. 20–30%, co w Ice Casino forum praktyce oznacza, że jakaś wygrana wypada średnio co 3–5 spinów, choć jej wartość bywa minimalna.

Jakość dźwięku w nowych tytułach

Nowe sloty coraz częściej korzystają z nagrań w jakości 48 kHz i miksu pseudo-surround; według ankiet aż 30–40% graczy deklaruje, że muzyka i Pelican Casino jak wyplacic efekty dźwiękowe mają wpływ na wybór gry, zwłaszcza na słuchawkach.

Sloty mobilne w Polsce

Aż 74% gier slotowych uruchamianych jest z telefonu, co sprawia, że Vulkan Vegas przystosowuje wszystkie sloty do płynnej gry na ekranach dotykowych.

Wielu użytkowników ceni możliwość filtracji gier według dostawcy, dlatego katalog dostępny w Verde Casino obejmuje rozbudowane opcje sortowania dla wygodniejszego wyboru tytułów.

Linkowanie do regulatora

Strony, które poważnie traktują compliance, często linkują do MF – Departament Gier i wyjaśniają użytkownikowi kompetencje urzędu; taki element podnosi wiarygodność również brandów kasynowych w stylu Bet Casino apk.

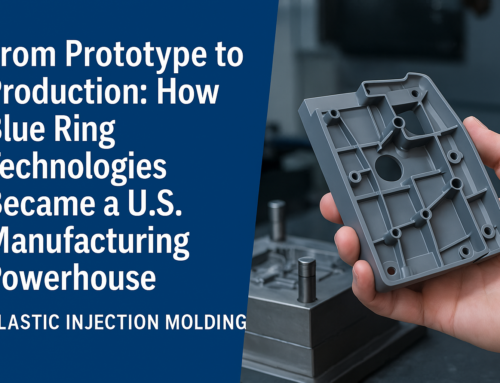

Why Manufacturing a Dog Toy at Blue Ring Technologies Beats Going to China

When launching a new product—like a dog toy—it’s tempting to chase the lowest cost overseas. But many companies end up paying more in the long run. At Blue Ring Technologies, we help consumer brands manufacture smarter by keeping production here in the U.S., with full control, faster iterations, and guaranteed mold ownership.

Let’s break it down with a real-world example: a molded dog toy made from FDA-approved TPE (thermoplastic elastomer).

🧸 Example Product: A Custom FDA-Approved TPE Dog Toy

Imagine you’re developing a chewable dog bone made from food-safe TPE. It needs your logo molded in, and you want to start with a 5,000-unit run.

🇨🇳 The China Approach: Looks Cheaper, Costs More

Here’s what overseas manufacturing often involves:

- Tooling cost: $6,000–$10,000

- Lead time: 4–6 weeks (similar to U.S. lead time)

- MOQ: Often 10,000+ units

- Freight: $2,000–$5,000 per container

- Tariffs & duties: 8–25% depending on materials

- Communication lag: Time zones, language barriers

- Quality risk: Delayed discovery of issues

- IP exposure: Limited enforcement across borders

🔒 You likely don’t truly own the mold.

Even if you paid for it, many Chinese manufacturers will not release the tool if you want to switch vendors. Some will even reuse your design without permission.

🇺🇸 The Blue Ring Technologies Approach: Control, Clarity, and Confidence

Yes—our tooling cost and lead time are comparable, but the value you get is far greater:

- ✅ You own your mold—period. No fine print.

- 🔁 Smaller batch runs welcome—start as low as 1,000 units

- 📦 No international shipping delays or customs issues

- 💬 Direct access to U.S. engineers for design and DFM support

- 🧪 FDA-approved TPE with full traceability

- 🛠️ Tooling built in-house or locally—quicker adjustments, faster repairs

- 🔍 Real-time quality control & accountability

We’re not just a vendor—we’re a partner committed to long-term success for your brand.

💡 Total Cost of Ownership Wins in the U.S.

When you account for:

- Delays

- Risk of mold loss or disputes

- Communication and rework costs

- Tariffs, freight, and minimum order quantities

- Quality inconsistencies

…it’s clear that U.S. manufacturing delivers more flexibility, speed, and value—especially for consumer products like toys, tools, and personal care items.

🐶 Final Thoughts

Your dog toy isn’t just a piece of plastic—it represents your brand, your vision, and your investment. At Blue Ring Technologies, we provide in-house plastic injection molding using FDA-grade materials, backed by a team that understands how to get great products made, fast and right.

Build smarter. Build safer. Build it here.

Share This Story, Choose Your Platform!