How Injection Molding Works If there is one machine that never fails to impress, it is our Injection Molding Machine. These huge pieces of equipment are true engineering marvels. Essentially, this machine injects plastic material at high pressure into a mold or cavity to create a useful plastic part. Simply look around at the products and items around you… the importance of this process is clear.

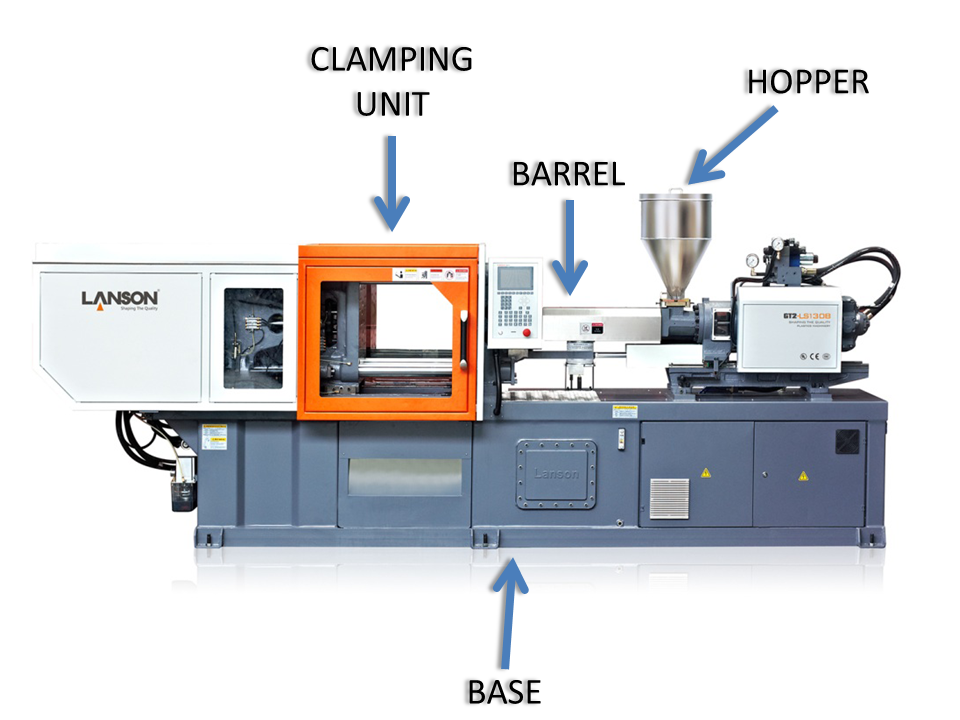

An injection molding machine consists of four major components: The Base, The Hopper, The Barrel, and the Clamping Unit. The base of the injection molding machine supports all the other components, as well as the electronics for all the control systems needed to run the machine. The electronics on this machine have to regulate a range of heaters, hydraulics, and sensors, as well as the injection pressure. The Hopper is where the plastic material is poured into the machine before the injection molding process can begin. The Hopper usually contains a dryer unit to keep moisture away from the plastic material. You will also find that it contains small magnets to prevent any harmful metallic particles from entering the machine. From the Hopper, the plastic material is poured into the next major component –the Barrel. The Barrel is the part of the injection molding machine that heats the plastic material into a molten state. This allows the plastic to flow through the barrel, where the screw inside the barrel injects the plastic into molds or cavities in the Clamping Unit. The temperature in the barrel needs to be properly regulated to maintain the appropriate temperature for different types of plastic material. For example, a Nylon base plastic will require a higher temperature than an HDPE plastic. Finally, the process reaches the Clamping Unit. The clamping unit consists of two large plates that hold the actual mold. A mold consists of two steel parts that are fastened to each of the large plates on the clamping unit. When the Injection Molding machine is ready to inject plastic into the mold or cavity, the clamping unit closes the two independent plates and allows the plastic to flow into the cavity to create the part. The plastic part is then cooled into a solid. Once the plastic is cool enough, the clamping unit simply opens the mold and the part falls out, to be collected in a bin. At Blue Ring Technologies, we are one of the only companies with our own full service in-house injection molding machines serving the greater Fort Lauderdale and Miami area, including Davie, Cooper City, Plantation, Weston, Sunrise, Hollywood, Pembroke Pines, Miramar, Dania, Aventura, Coral Springs, Hialeah, Coral Gables, West Miami, Westchester, Sweet Water, Miami Lakes, Kendell, Homestead, Doral, Key Biscayne, Miami Beach, Opa-Locka, Palmetto, Pinecrest, and Sunny Isles. Example of our own Injection Molding Machine:

When our clients need speed we will use this machine:

https://youtu.be/EZat8nEgmiA